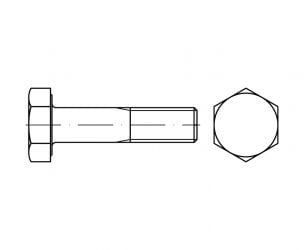

Bolts for HV preloaded assemblies

Bolts for HV preloaded assemblies are suitable for making preloaded bolted assemblies in steel and metal structures in accordance with the currently applicable DIN EN 14399-4 standard.

Currently, the abbreviation HV stands for HV screw set systems, which include hexagonal head screws and nuts. You can still come across the old marking, in which the letter H indicated the high grade of the material from which the screw was made, and V stood for a preloaded assembly, i.e. the condition of the screw.

Bolts for HV preloaded assemblies – scope of standardization

Bolts for HV preloaded assemblies are standardized for:

dimensional ranges from M12 to M36 inclusive,

strength classes 10.9/10.

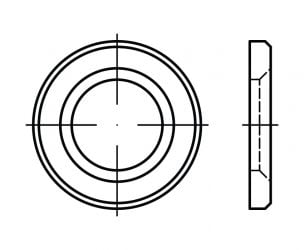

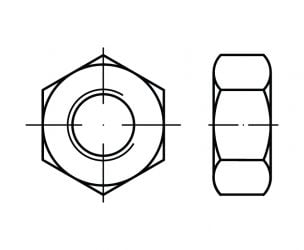

HV preloaded bolts made in accordance with DIN EN 14399-4 (older DIN 6914) are used together with HV nuts DIN EN 14399-4 (previous DIN 6915) and washers DIN EN 14399-6 (former DIN 6916). , DIN 6917, DIN 6918.

The DIN EN 1090-2 standards (older DIN 18800-7) provide guidelines for making or installing assemblies.

Bolts for HV preloaded assemblies with enlarged head size for wrenches

HV preloaded bolts with an enlarged head size have a larger underside of the head. The forces are distributed over a larger area and thus cause lower unit pressure and lower settlement.

These screws also have a larger underside radius of the head. This means less notch action and better fatigue durability.

Precisely defined friction parameters give control over compression.

The CE marking stamped on the screw head indicates that it is a regulated construction product that meets certain requirements.

Bolts for HV preloaded assemblies with an enlarged head size, class 10.9, allow for, compared to ordinary bolts, better use of the strength of the bolt and, consequently, the use of fewer bolts or the use of bolts with smaller dimensions.

What anti-corrosion protection does bolts for HV preloaded assemblies have?

The nuts are hot dip galvanized (according to DIN EN ISO 10684) and covered with a layer of MoS2. The thickness of the zinc layer is 40 µm. For the screw thread to be covered with a layer of zinc, the threads must be made within the limit dimensions before galvanizing.

HV nuts have an excess thread in tolerance class 6AZ.

The ungalvanized thread in the nut is also protected against corrosion after assembly. This is made possible by the thread coating of the screw shank. Since any changes in conditions during production, anti-corrosion protection and lubrication can impact the correct operation of preloaded screw assemblies, it is very important that the screw set comes from one manufacturer who will guarantee the operation of the entire assembly, not the individual components.

Bolts for HV preloaded assemblies – how to handle them during transport?

The basic requirement is to use HV sets from the same manufacturer and purchased as sets, not individual parts.

All components of the HV set must be protected against corrosion and dirt.

During transport, pay special attention to ensure that the threads are not damaged.

Rules for installing bolts for HV preloaded assemblies

To equalize the length of the compression part, up to three washers are allowed on the side of the assembly that is not rotated. Their total thickness cannot be greater than 12 mm.

The washer should be installed so that the chamfered edge faces outwards. This is because the chamfered edge adapts better to the radius of the underside of the head.

Preloaded assemblies must not be unscrewed. The disassembled set must be replaced with a new one. Therefore, after installation, bolts for HV preloaded assemblies should be positioned so that the markings on the bolt head and nut are visible.

Preloaded assemblies are made by tightening the nut. If it is necessary to tighten the head of a bolt for HV preloaded assemblies, the bolt should be lubricated on the head side. In a properly made assembly, the thread of the screw for HV preloaded assemblies must protrude at least one thread above the nut.